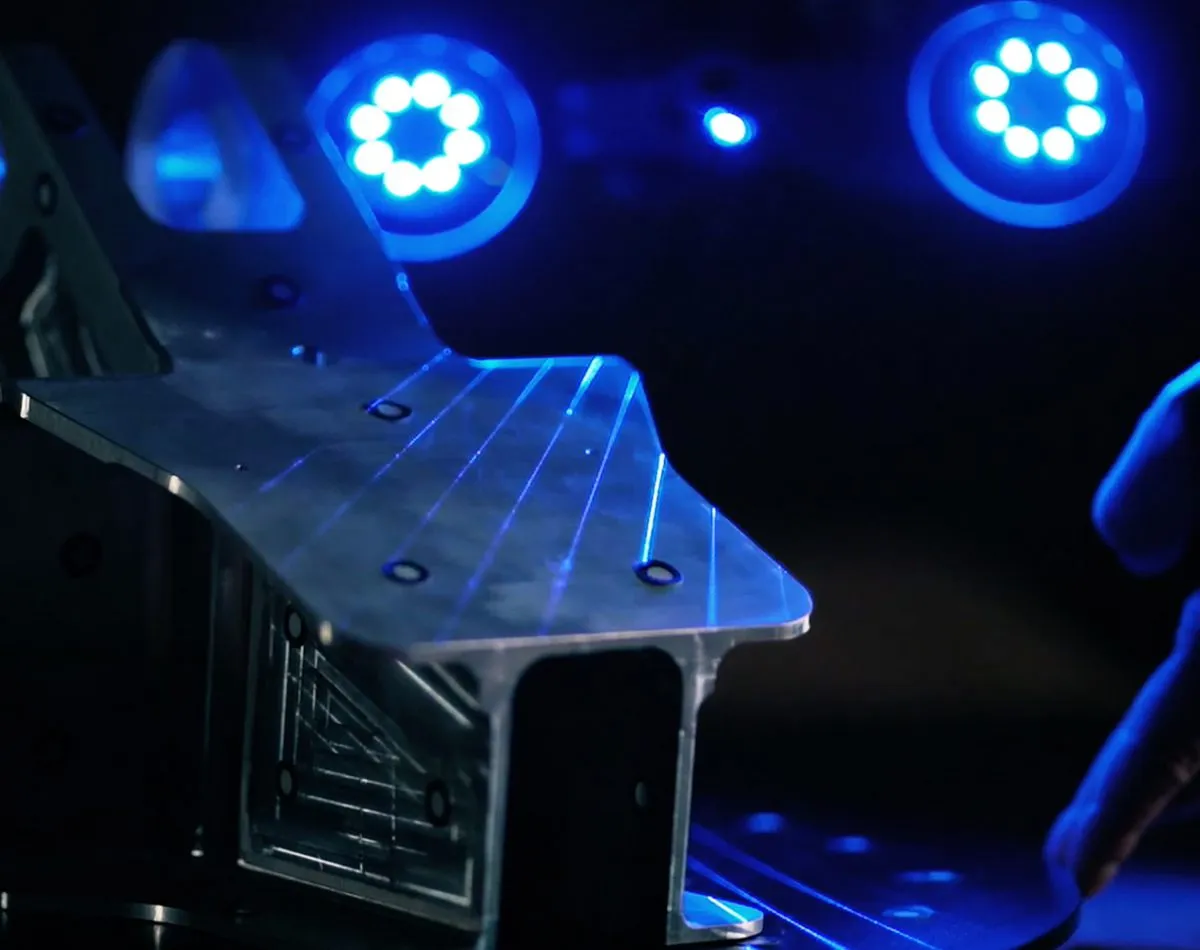

• Aluminum alloys, Steel and Stainless Steel, Titanium etc. processing of materials. • Ability to process 3, 5 and 7 axis using high technology. • Part reset with electronic touch probe. • Ability to process parts with vacuum fixing method. • Use of shrink tool holder. • Precise cutting tool measurement with Zoller tool presetter.Machining

Programs Used • Seimens NX • Catia • Vericut • PC-Dmis Cad++ Orsan OPS constantly updates and uses the latest versions of the computer programs it usesPrograms Used

Design • Apparatus design and production of all products that will enter production • Special tool holder design and production • Design and production of precision casting molds • Simulation of moving parts • Vacuum apparatus design • Reverse engineeringDesign

To provide continuous customer satisfaction by meeting the needs and expectations of our customers completely and on time;

To become a world company by determining target markets and increasing exports, to increase our level of competition;

To comply with legal regulations by considering the interests of the companies and institutions we serve;

To continuously improve the effectiveness of the Quality Management System;

To increase productivity by constantly renewing machine quality and technology by following technology and innovations;

To lead the sector by making new designs for the benefit of its customers;

To consistently achieve quality, cost and timing targets;

To ensure effective participation by giving responsibility and authority to its employees; is our quality policy.