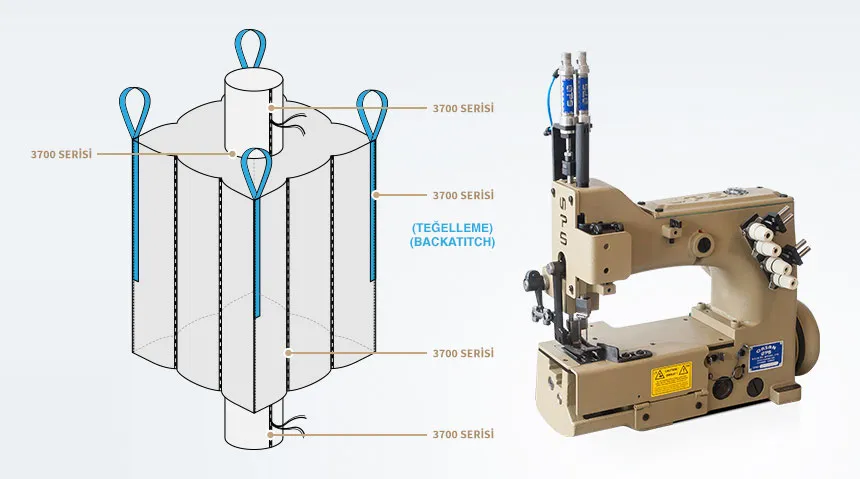

It is a full oil chain stitch sewing machine developed for big bag manufacturers. It is used for baffle panels, top and bottom spouts and column tack. Suitable for light to medium duty works. Due to its effective feed dog and presser foot system, it can make regular and identical traction in thin and thick, with or without filler cord works. It is faster and longer lasting than similar machines in the same class, thanks to its bearing system at the feed dog transport lever.

| Machine Model | 3700-2H | 3700-H |

|---|---|---|

| NEEDLE TYPE | UY 143 GS 200/25 | UY 143 GS 200/25 |

| NUMBER OF NEEDLES | 2 | 1 |

| YARN TYPE | Multiflament | Mono/Multi Flament |

| NUMBER OF YARNS | 4 | 2 |

| YARN DENIER RANGE | 1000-2500 | 1000-2500 |

| DISTANCE BETWEEN NEEDLES | 6,5mm | N/A |

| STITCH TYPE | Double Chain | Single Chain |

| STITCH LENGHT RANGE | 5-10mm | 5-10mm |

| TRANSPORT SYSTEM | Double (Top and Bottom) | Double (Top and Bottom) |

| PRESSING SYSTEM | Pneumatic | Pneumatic |

| PRESSING FOOT TYPE | Shock Absorber | Shock Absorber |

| MAXIMUM RPM | 2600 | 2600 |